Reliable Precision Machining, Prototyping, and Custom Parts Production.

Your requirements are distinct, and we offer the solutions they deserve.

- Affordable Pricing, Save Up to 30%

- Rapid Lead Times Within 7 Days

- Precision Accuracy to ±0.005mm

- Worldwide Shipping

- Genuine Facility Open for Visits

25+Years

CNC Expertise

500+

Global Clients

1M+Parts

Custom Parts Delivered

99.8%

Customer Approval

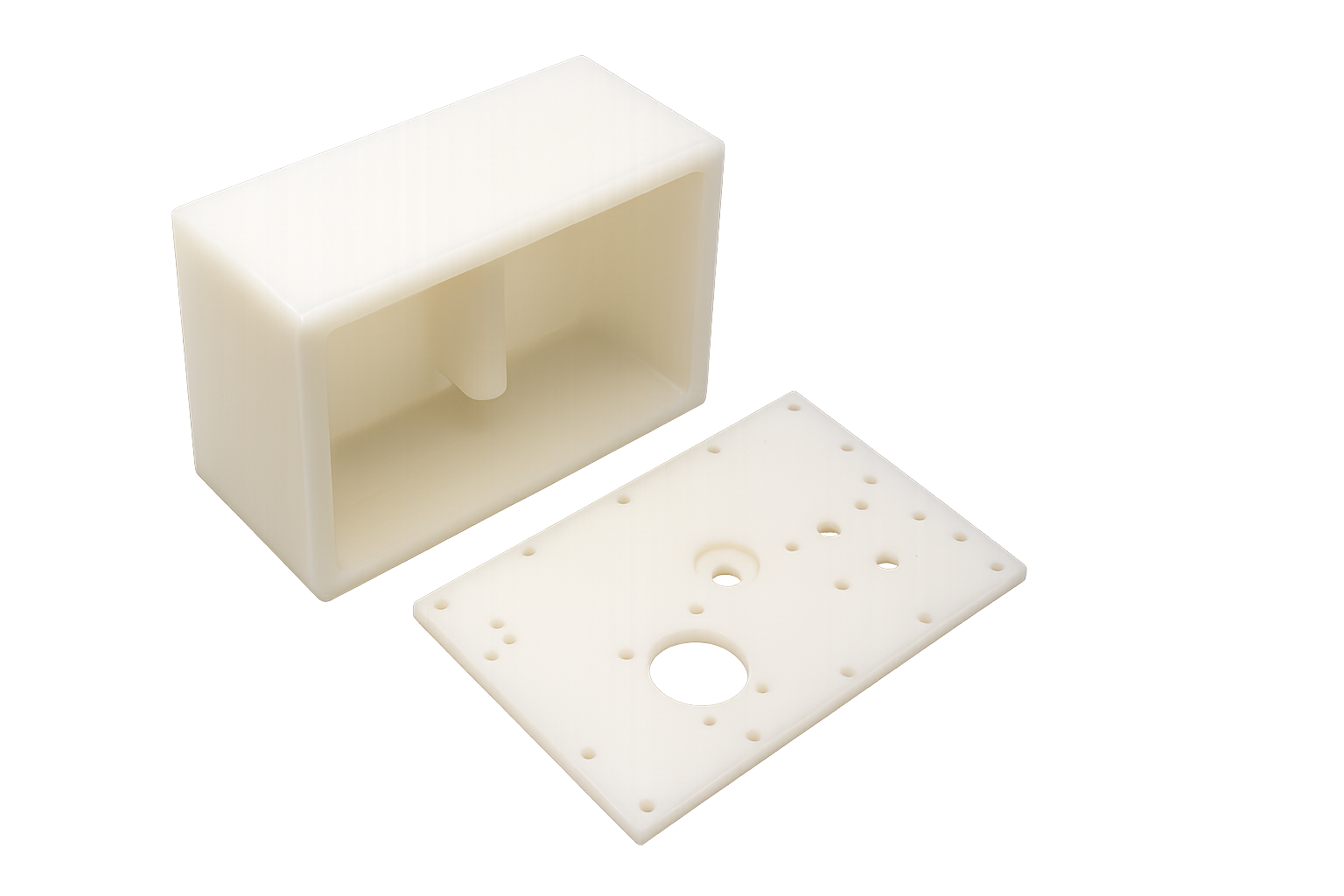

What We Can Manufacture

With our extensive machining expertise, Sochain Precision offers reliable prototyping, small-batch, and mass production services tailored to your specific design requirements. Our professional team collaborates closely with you, transforming your innovative concepts into reality using advanced CNC machinery and guaranteeing timely delivery of your components.

If you’re searching for a trusted machining partner in China, we are your best choice!

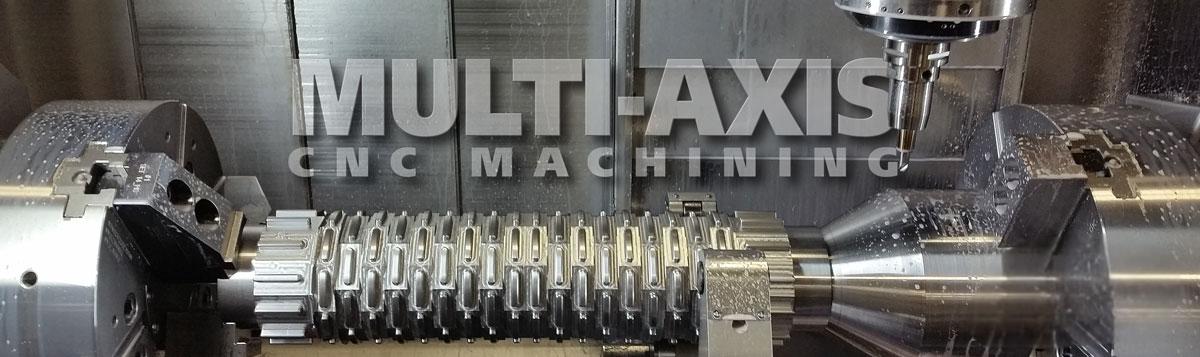

CNC Machining

Precision CNC Turning, CNC Milling, 3 Axis Machining, 4 Axis Machining, 5 Axis Machining Solutions for both basic and intricate component geometries.

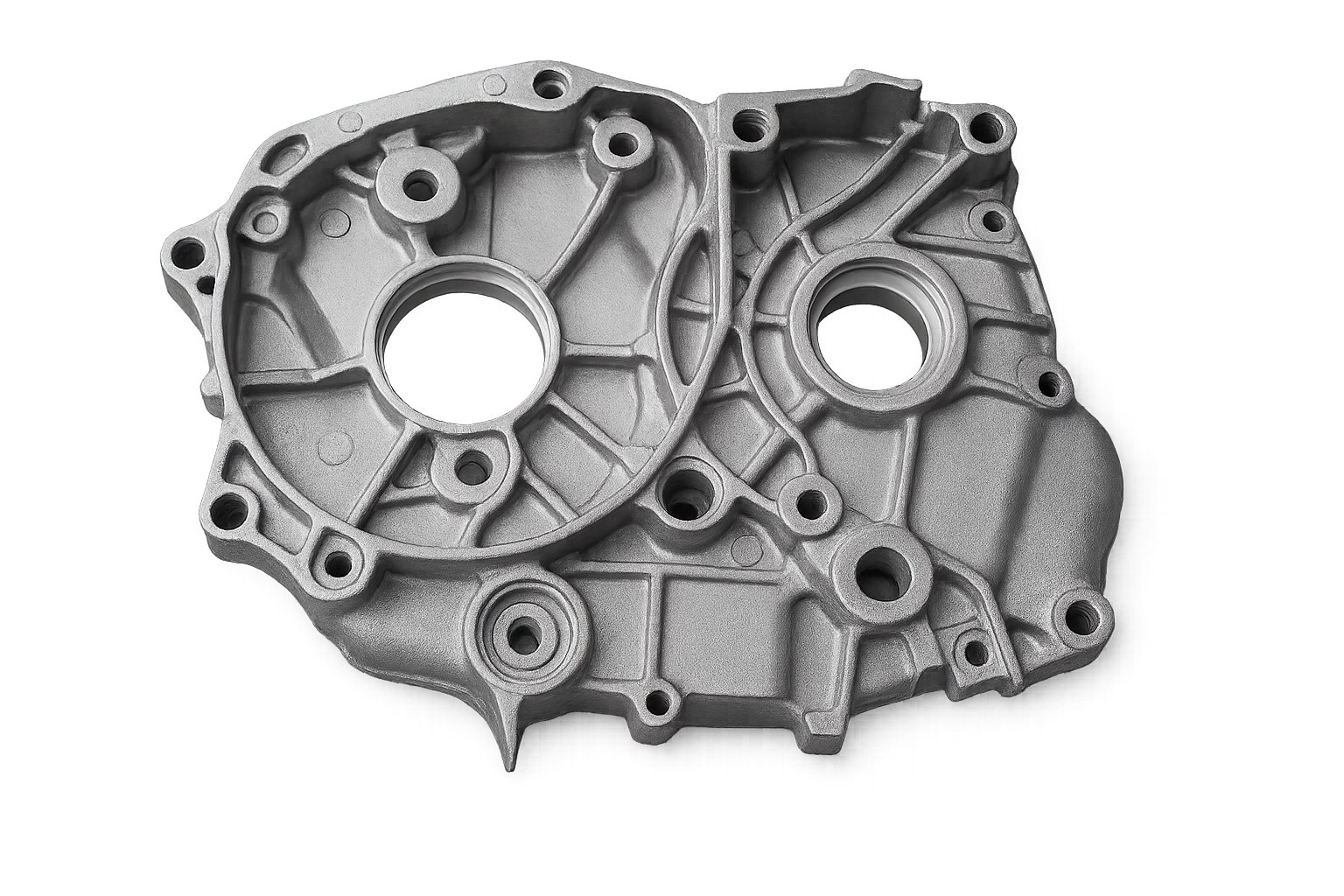

Die Casting

Both hot chamber and cold chamber die casting, capable of manufacturing components with intricate geometries, tight tolerances, and excellent mechanical strength.

Plastic Injection Molding

Select from countless combinations of materials, surface treatments, dimensional tolerances, and quality certifications to suit your production requirements.

Customized On-Demand Production Services

Whether you require prototypes for design validation or large-scale manufacturing of final components, Sochain Precision provides the ideal solution for

Fast Prototyping

1-50 Pieces via CNC Milling, Laser Cutting, and Additional Methods.

Small Batch

CNC Precision Machining and Sheet Metal Processing.

Massive Production

Reliable Part Quality, CNC Machining, Die Casting etc.

Outsourcing Support

All-in-One Manufacturing Partner, Custom Production Solutions,.

Over 100 Material Options Available

Metals

Choose the perfect material for your application by exploring its distinct properties.

Aluminum

Lightweight, corrosion-resistant, easy to machine, ideal for aerospace and consumer products.

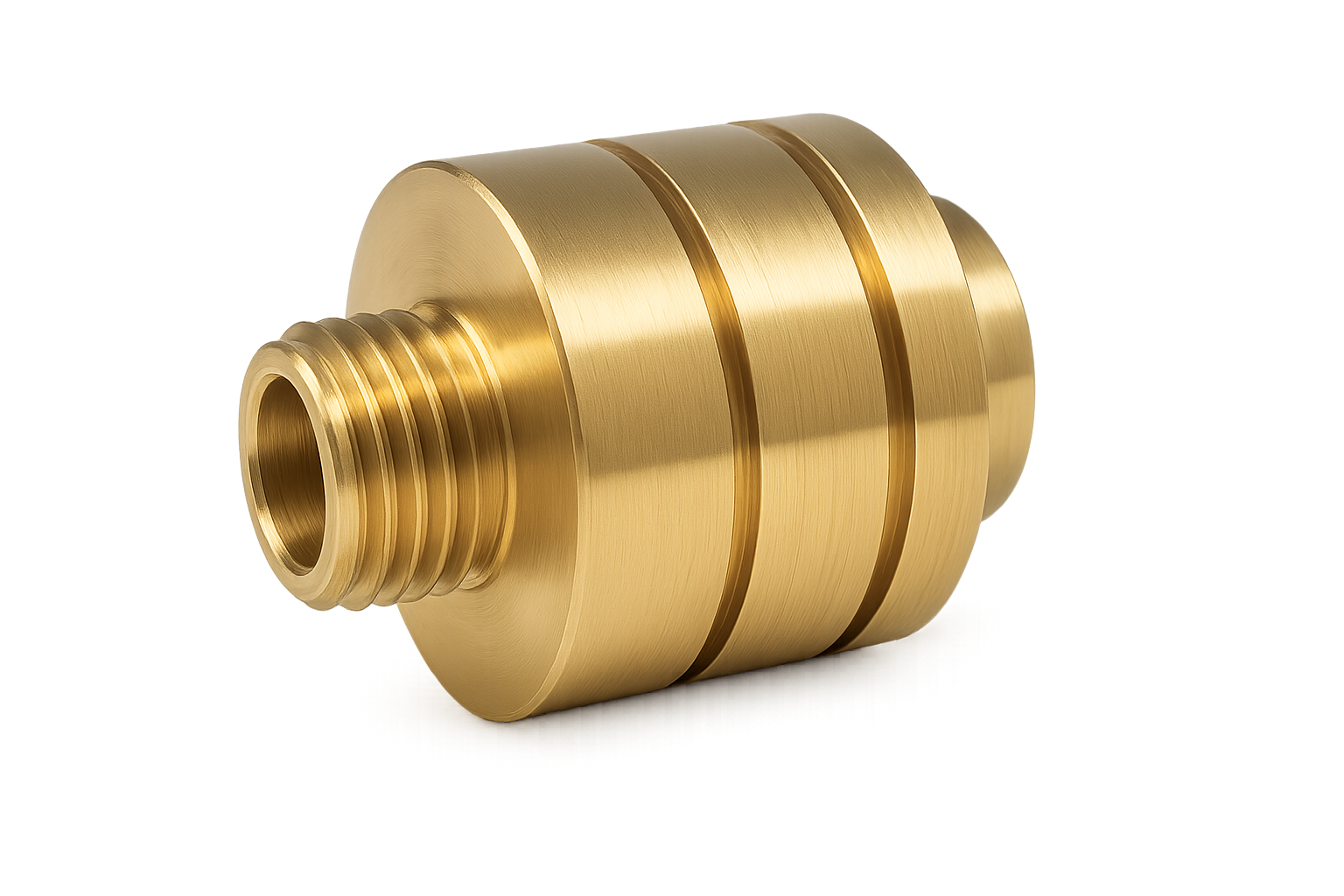

Brass

Excellent machinability and corrosion resistance with a decorative gold-like appearance.

Stainless Steel

Highly durable and corrosion-resistant, perfect for medical, food, and marine applications.

Steel

Strong, tough, and versatile, commonly used in structural and industrial parts.

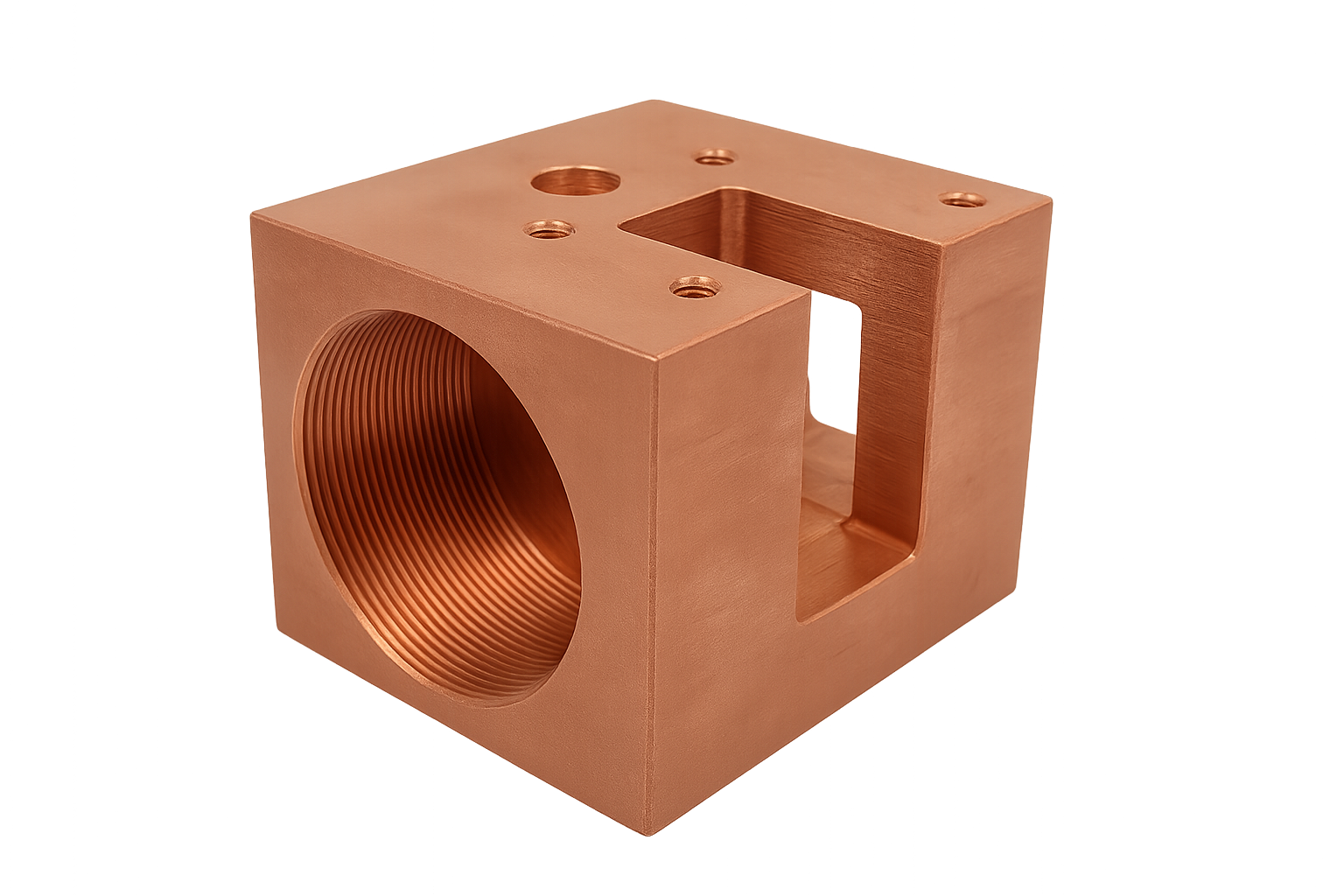

Copper

Exceptional electrical and thermal conductivity, widely used in electrical and plumbing systems.

Titanium

Extremely strong yet lightweight, with outstanding corrosion resistance for aerospace and medical use.

Cast lron

Excellent wear resistance and vibration damping, ideal for heavy-duty machinery bases.

Tool Steel

Known for its hardness and heat resistance, perfect for cutting tools and dies.

Bronze

Strong, wear-resistant, and corrosion-proof, often used in bearings and bushings.

Magnesium

Ultra-lightweight with good strength-to-weight ratio, commonly used in automotive and electronics.

Plastics

Understanding each plastic’s unique characteristics can greatly improve your product’s performance.

POM

Low-friction, high-stiffness plastic ideal for precision mechanical parts like gears and bearings.

ABS

Tough, impact-resistant, and easy to mold, commonly used in consumer electronics and automotive parts.

Nylon (PA)

Strong, wear-resistant, and flexible, widely used for mechanical and structural components.

PEEK

High-performance thermoplastic with excellent heat, chemical, and wear resistance for demanding environments.

PTFE (Teflon)

Extremely low friction and high chemical resistance, ideal for seals, gaskets, and non-stick coatings.

PVC

Rigid, flame-retardant, and cost-effective, widely used in piping, construction, and electrical insulation.

PMMA (Acrylic)

Transparent, UV-resistant plastic often used as a lightweight and shatterproof alternative to glass.

PEI (Ultem)

High-strength, flame-resistant thermoplastic suitable for aerospace, medical, and electronic components.

PAI

Exceptional thermal stability and mechanical strength, used in high-performance industrial applications.

HDPE

Strong, chemical-resistant, and lightweight, ideal for containers, piping, and outdoor applications.

What Industries We Serve

With two decades of precision manufacturing experience, we’ve proudly served a wide range of industries including electronics, automation, telecommunications, transportation, heavy machinery, renewable energy, instrumentation, and more.

Our strong grasp of each sector’s specific demands, quality standards, and functional needs is what distinguishes us and delivers real value to our partners!

Why Choose Sochain?

Skilled Engineers

Leveraging our technical know-how, we’ll evaluate your part’s feasibility, recommending suitable materials and design improvements to deliver cost-effective manufacturing solutions tailored to your project.

Tight Tolerance Part

Sochain Precision’s dedication to exacting standards ensures every part meets the tightest tolerances, guaranteeing flawless execution for your critical projects.

Cost-Saving Solutions

Achieve up to 20–30% cost savings with our streamlined machining workflows and efficient resource control, delivering competitive pricing without sacrificing quality.

High Quality Standard

As an ISO 9001:2015 certified manufacturer, we ensure consistent quality backed by RoHS certifications, verified material traceability, and comprehensive inspection reports for your confidence and trust.

Customer Satisfaction-Oriented

We’re committed to providing a seamless journey, delivering tailored support and clear communication from your first inquiry through production, delivery, and after-sales care.

Rapid Turnaround Time

Urgent projects are in good hands with us, as we deliver fast production cycles while maintaining the precision and quality of every CNC machined part.

Our Trusted Partners!

We focus on aligning with your vision, supporting you in overcoming obstacles and turning your ideas into success.

“Sochain Precision provided fast and accurate service for our high-quality CNC components. They offered various machining options and material selections that perfectly matched our budget, timeline, and technical needs. Highly recommended!”

"I can't tell you how pleased I am to work with your team—the parts are absolutely perfect! The quality exceeded my expectations! Please extend my sincere appreciation to the CNC machinists who made this happen! Also, thank you for the outstanding packaging!"

"We checked the parts, all dimensions were well within tolerance, and the surface finish on the machined areas is excellent. Sochain has consistently delivered exactly what we were looking for."

Sochain Precision has always provided exactly what we asked for. We’ve received components with precise features, perfect finishes, and on-time delivery. Their responsive team ensures a smooth and efficient production process.

Blog & Latest Updates

Comprehensive Guide to Machining Processes: Techniques, Applications, and Considerations

-

Posted by

jason.li@sochain-precision.com

- 0 comments

Multi-Axis CNC Machining: In-Depth Guide to Technology, Benefits, and Applications

-

Posted by

jason.li@sochain-precision.com

- 0 comments

Form Milling: A Comprehensive Guide to Principles, Tools, Advantages, and Industrial Applications

-

Posted by

jason.li@sochain-precision.com

- 0 comments